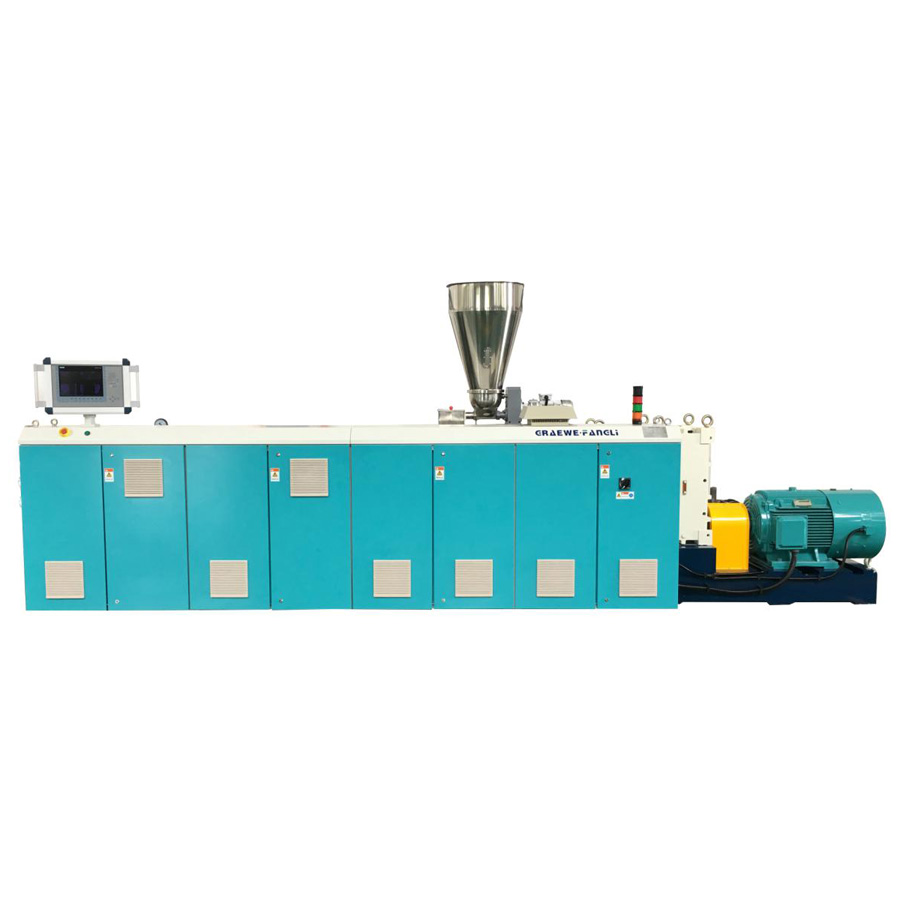

Counter Rotating Parallel Type Twin-screw Extruder

The FLSP 36 length-diameter ratio series counter rotating parallel twin screw extruder introduces the newest technology from Germany. The high-end G type adopts EU standards, and the high-end U type adopts North American standards. It is specially applied to a counter-rotating parallel twin screw ex......

Send Inquiry

Product Description

The FLSP 36 length-diameter ratio series counter rotating parallel twin screw extruder introduces the newest technology from Germany. The high-end G type adopts EU standards, and the high-end U type adopts North American standards. It is specially applied to a counter-rotating parallel twin screw extruder for extruding UPVC, PVC-UH, and PVC-O pipes. Compared with the traditional counter-rotating parallel twin screw extruders with the L/D ratio of 26 or 28, this product has a higher unit power extrusion capacity and energy saving effect, a better melt uniform mixing effect and plasticizing effect, a wider processing window, and flexibility for different raw materials, making it ideal equipment for extruding high-performance rigid PVC-UH pipes.

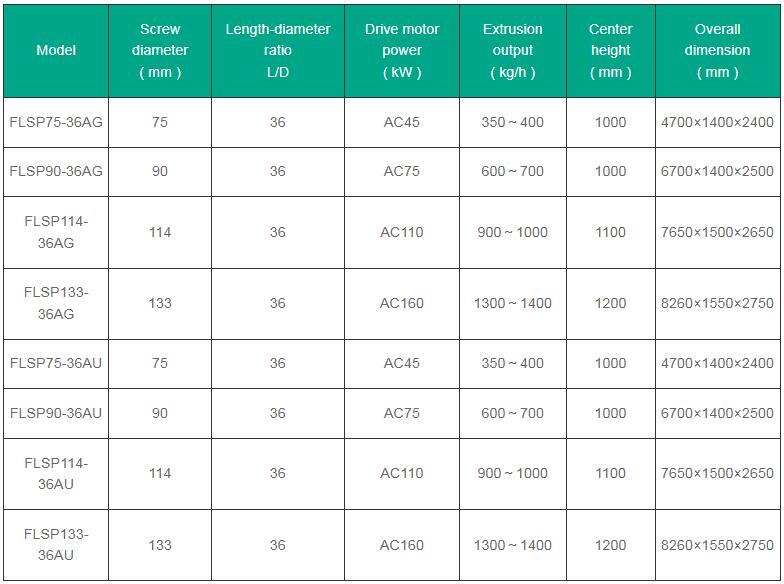

Counter Rotating Parallel Type Twin-screw Extruder Product Parameter

Counter Rotating Parallel Type Twin-screw Extruder Product Feature And Application

1.The screw is treated by nitriding and hard chromium plating, and the super length diameter ratio structure realizes high quality and high yield extrusion.

2.The cylinder adopts nitriding treatment, and the double exhaust port structure of natural exhaust + vacuum exhaust ensures the full discharge and separation of volatile matter and powder solid matter, with 3-stage spiral groove circulating water cooling system.

3.The gearbox adopts the special hard tooth surface gearbox of Taiwan Sanlong ultra high torque counter rotating twin screw extruder.

4.The screw core adopts distilled water internal circulation temperature regulation system, which reduces the maintenance cost.

5.The exhaust system adopts the dual exhaust system of natural exhaust and vacuum exhaust.

6.The power consumption display monitors the energy consumption status constantly.

7.Siemens 12 "LCD microcomputer control system

8.ABB frequency converter

9.Equipped with a sensing and measuring device for melt pressure and melt temperature to realize separate detection